INDUSTRIAL HOSE EXPERTS

Chesapeake Bay Rubber & Gasket offers the very finest in industrial hose assemblies. Working closely with Campbell Fittings and other industry leaders in hose crimping technology, we house multiple industrial hose crimper and two Band-It hose banding machines. This equipment allows us the sophistication to produce hose systems for demanding applications and the speed to couple hoses quickly for immediate delivery. All hose can be hydrostatically tested.

Hose Crimping

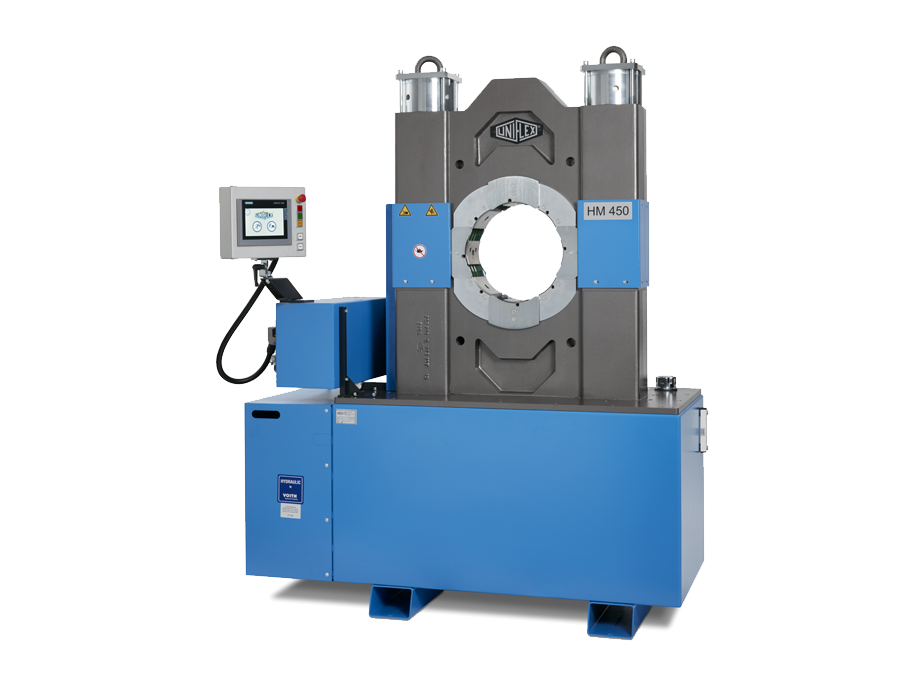

Chesapeake Bay Rubber & Gasket prides itself on quality service and quality products. In an effort to improve quality we have acquired multiple hose crimping machines. With powerful crimping force and a range capable of crimping any hose from ½” ID to 6” ID, our machine helps set Chesapeake Bay Rubber apart from the rest. Working closely with industry leaders such as Finn Power, Uniflex, Campbell Fittings, and PT Coupling, we have been developing sophisticated hose crimping solutions on site.

How it works

When the hose is fitted with the appropriate fitting a sleeve or ferrule made from a suitable metal (plated steel, stainless steel) is placed around the hose aligned with the shank of the fitting. When the end of the hose is placed into the crimper opening the operator activates the crimping mechanism and the dies close down on to the sleeve or ferrule. The dies close until they reach the “crimp spec” or “crimp diameter” – a predetermined spec calculated by measuring the hose wall, shank diameter, and sleeve/ferrule thickness. Once a “crimp spec” is determined for a certain assembly it can be programmed into the computer and is repeatable in the event of future orders.

Why Crimped Hose?

Crimped hose assemblies are superior to banded and swaged hoses for many reasons. When a fitting is crimped to a hose there is more retention along a larger area of the shank or barb. This provides a much higher safety factor for complete assemblies than banding can offer. More retention also means a significant decrease in possible leaks. Not even swaged assemblies hold fittings this well. When the excess on a band clamp is broken off after being tightened it can leave a sharp edge that can cut the handler. A crimped sleeve or ferrule has a smooth finish that is safe to handle and also looks much better.